Theme: Universities’ and business’ shared role in regional development

Theme: Universities’ and business’ shared role in regional development

Authors: Amer Gaffar (Manchester Metropolitan University); Dr Ian Madley (Manchester Metropolitan University); Prof Bamidele Adebisi (Manchester Metropolitan University).

Keywords: Decarbonisation; Local Energy; Skills; Economic Growth.

Abstract: Greater Manchester (GM) has committed to carbon neutrality by 2038. There is a 97m tonnes carbon emission gap between solutions currently available and a net zero budget. To bridge this innovation gap under the leadership of the Greater Manchester Combined Authority the agency brings together: Bruntwood, Hitachi, MMU, UoM, GM Growth Company, SSE and UoS to support R&D and innovation initiatives focused on customer pull to enable rapid deployment of new and emerging technologies, services and business models to meet the challenge of GM becoming a carbon neutral city-region by 2038, drive skills development and deliver economic growth.

The need for an Energy Innovation Agency

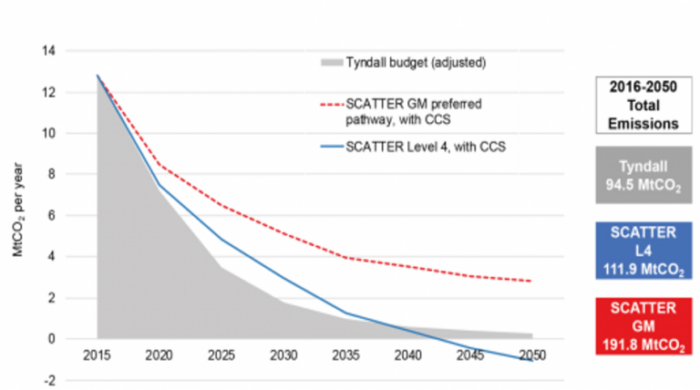

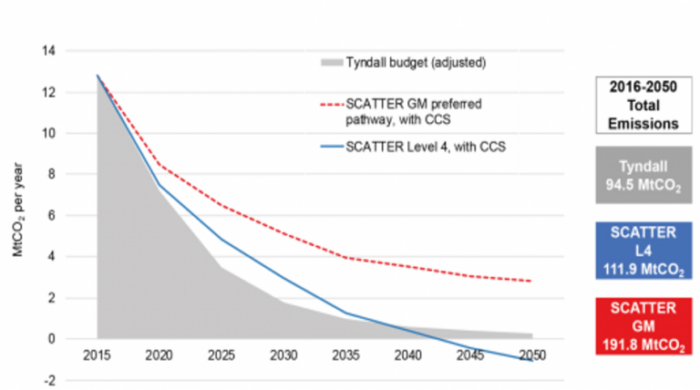

The Mayor for Greater Manchester Combined Authority (GMCA) has committed the city region to carbon neutrality by 2038. An analysis of the implications of the Paris Climate Change Agreement for Greater Manchester (GM) (Figure 1) has identified that there is a 97m tonnes carbon emission gap between solutions currently available and the actions needed to reach net zero. We refer to this as the Innovation Gap.

Achievable implementation of Scatter methods

To bridge the GM innovation gap under the leadership of GMCA the agency brings together: Bruntwood, Hitachi, Manchester Metropolitan University, University of Manchester, SSE and University of Salford to support R&D and innovation initiatives focused on customer pull to enable rapid deployment of new and emerging technologies, services and business models (energy innovations) to meet the challenge of GM becoming a carbon neutral city-region by 2038, driving skills development and delivering economic growth.

Forming the Energy Innovation Agency

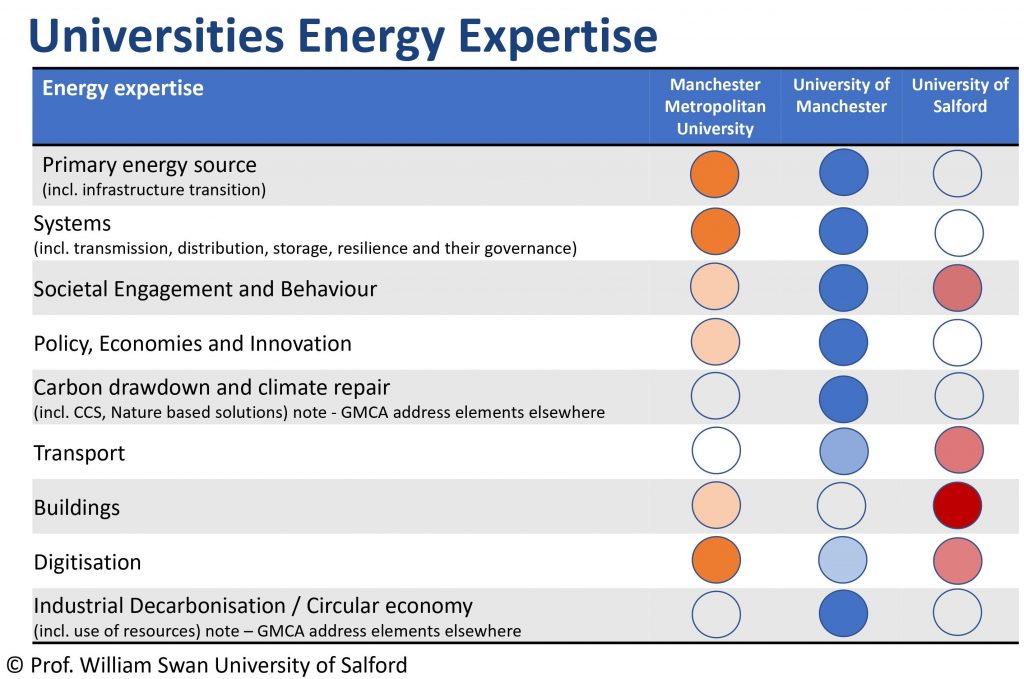

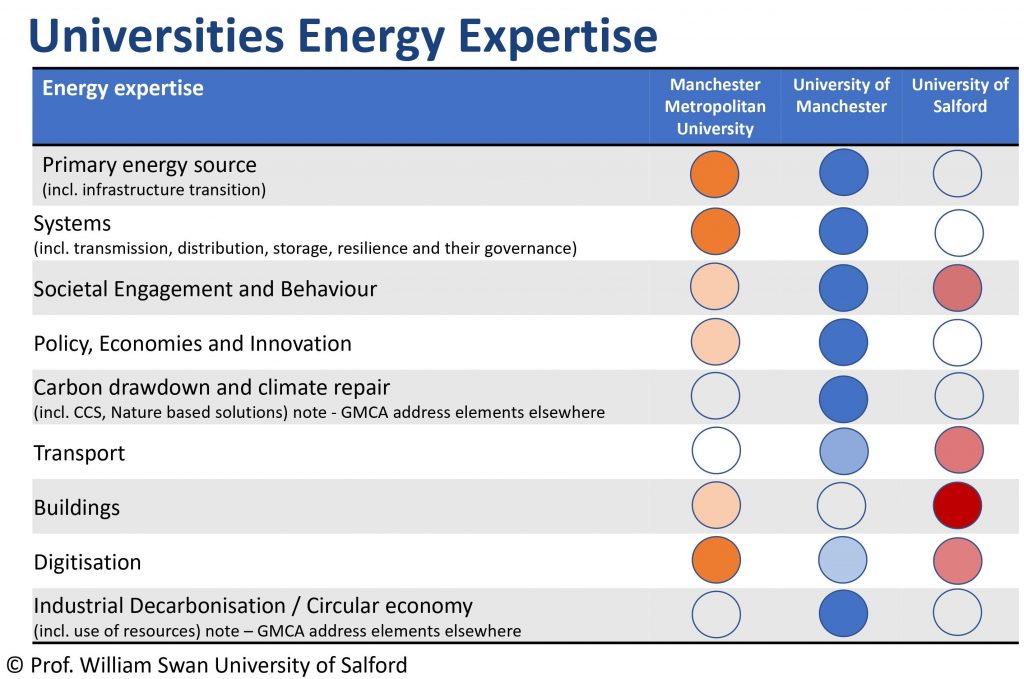

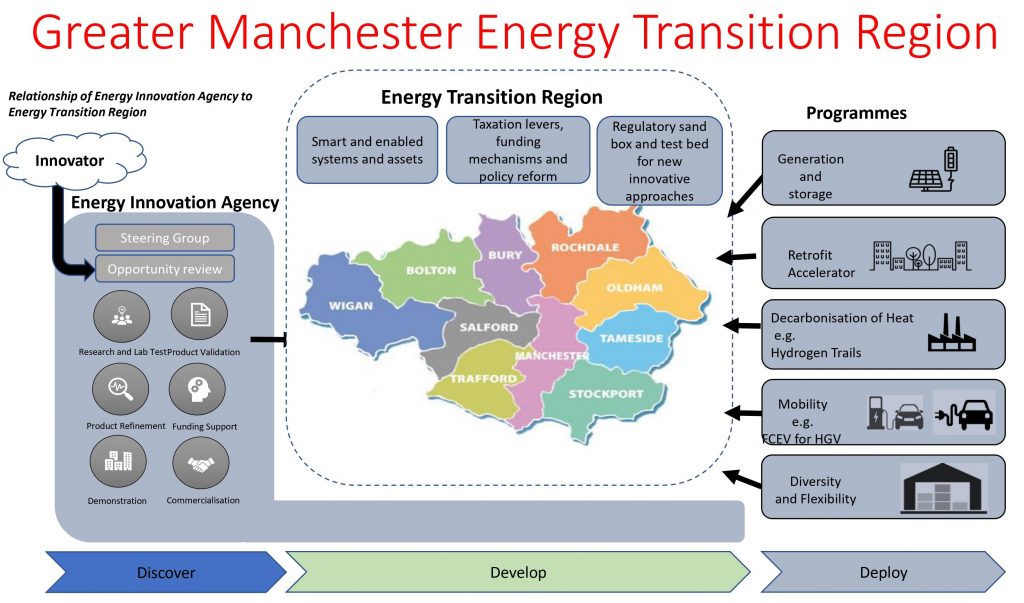

GMCA initially approached the city’s three universities to seek advice on how their academic expertise could be harnessed to help bridge the innovation gap. This quickly led to discussions between each of the universities that identified a wide pool of complementary, and largely non-competitive, areas of research expertise that could address the gap (Figure 2).

Figure 2 Research expertise by university partner – darker colour indicates a greater depth of expertise in the area.

It was also clear that the timescales needed to deliver city wide change would not fit within a traditional academic approach to research and knowledge transfer that required a public-private partnership.

At the core of this partnership approach are three key components.

- Public sector influence and leadership across both city region and local authority levels that enables new ways of working to be demonstrated and quickly built into local plans, can influence national policy and regulation, and convene wider public involvement.

- The business community, end-users and investors, in its widest sense, who have the need for change and can drive change by steering the development of the business and finance models that allow rapid large-scale adoption and deployment of innovation.

- Academic sector able to drive the underpinning research, access to research and test facilities to validate novel innovations, TRL and IP, and develop the skilled workforce needed.

Using existing networks, a core team comprising GMCA, Bruntwood, Hitachi, MMU, UoM, SSE and UoS came together to develop the business plan for the agency and to jointly provide the funding for the first three-years of the operation of the agency.

Vision, Aims and Objectives

To accelerate the energy transition towards a carbon-neutral economy by bridging the energy innovation gap, increasing the deployment of innovative energy solutions in GM and beyond, to speed-up the reduction of carbon emissions.

Aims:

- Innovation Exploitation: supporting and scaling the most promising decarbonised energy innovations to maximise the early adoption of effective carbon-neutral energy systems.

- Decarbonisation: reducing Greater Manchester’s carbon emissions from energy to meet our ambitious target to be a carbon-neutral city region by 2038

- Rapid Commercialisation: rapid transition of carbon-neutral energy innovations to full-scale integration.

- Investment: creating and promoting investment opportunities for carbon-neutral energy innovations and projects in the city region.

Objectives:

- Position Greater Manchester as a global destination of choice for those looking to create and deploy innovative net-zero energy solutions.

- Create a clear entry point, managed development, and validation pathway, for innovators to test, trial, and scale their most promising energy technologies and services in Greater Manchester.

- Enhance the connection between industry and academia “push” and customer “pull”, by putting innovative products, services, and projects in front of purchasers at the very earliest stage for advice and steer.

- Provide a dedicated vehicle to bid for competitive funding and for industry to generate investment value, pooling the very best innovations to solve key decarbonisation challenges.

- Link local investment to innovative products and projects, to enable rapid development and deployment where clear business cases are set out.

- Direct alignment to local and national policy and strategy, ensuring project delivery intelligently informs policy and vice-versa.

- Foster public confidence in new approaches and technologies, creating local skills and employment opportunities and improving access to cheaper, cleaner energy for all.

Scope

With a population of 2.8 million covering 1,277 km2 the ten metropolitan boroughs of GMCA comprises the second most populous urban area in the UK, outside of London. The scope and potential for the Energy Innovation Agency is huge.

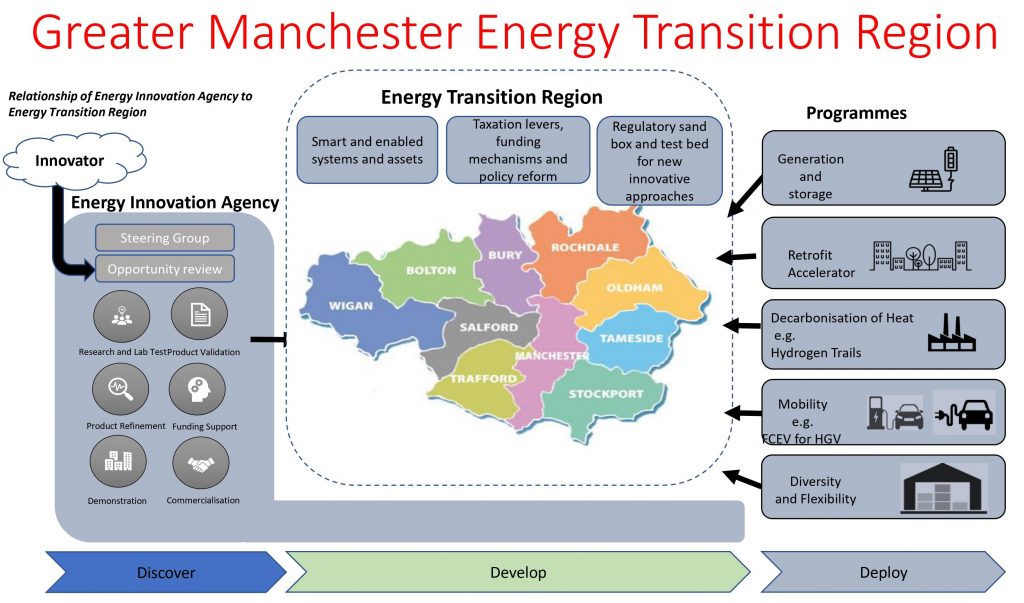

Figure 3 GMCA Energy Transition Region showing local authority boundaries.

Establishing the GM-city region area as an Energy Transition Region will provide the opportunity to develop the scale of deployment necessary to go beyond small-scale demonstration projects and develop the supply chains that can be replicated as a blue-print elsewhere in urban environments across the UK and internationally.

Progress to date

Following the investment by the founding partners a management team has been established within GMCA’s subsidiary “The Growth Company”. An independent board chaired by Peter Emery CEO ENWL has also been established.

The formal launch event will take place on 28th April 2022, at which a first challenge to the innovation community to bring forward solutions to decarbonise non-domestic buildings will be set.

Key contacts and further information

- David Schiele Energy Innovation Director david.schiele@energyinnovationagency.co.uk

- Dan Dickinson Business Development Lead daniel.dickinson@energyinnovationagency.co.uk

Case Study

Amer Gaffar, Director Manchester Fuel Cell Innovation Centre, Manchester Metropolitan University a.gaffar@mmu.ac.uk

References

[1] https://www.greatermanchester-ca.gov.uk/media/1986/5-year-plan-branded_3.pdf [2] Kuriakose, J., Anderson, K., Broderick, J., & Mclachlan, C. (2018). Quantifying the implications of the Paris Agreement for Greater Manchester. https://www.research.manchester.ac.uk/portal/files/83000155/Tyndall_Quantifying_Paris_for_Manchester_Report_FINAL_PUBLISHED_rev1.pdf

Any views, thoughts, and opinions expressed herein are solely that of the author(s) and do not necessarily reflect the views, opinions, policies, or position of the Engineering Professors’ Council or the Toolkit sponsors and supporters.