Theme: Research

Theme: Research

Authors: Dr Grazia Todeschini (King’s College London) and Kah Leong-Koo (National Grid UK)

Keywords: Electrical Engineering, Power Systems, Renewable Energy, Computer Model

Abstract: This case study deals with a collaboration between KCL and National Grid on a EPSRC project. The project deals with assessing the impact of renewable energy sources on the electricity grid. This assessment will be carried out by using a transmission grid model provided by National Grid and device models developed by KCL.

Topic of the case study

This case study deals with the development of advanced models to study the impact of renewable energy sources, and more in general, inverter-based devices, on the UK transmission grid. More specifically, this project focuses on the impacts in terms of voltage and current distortion. This topic is referred to as ‘power quality’ in the specialist literature.

Aims

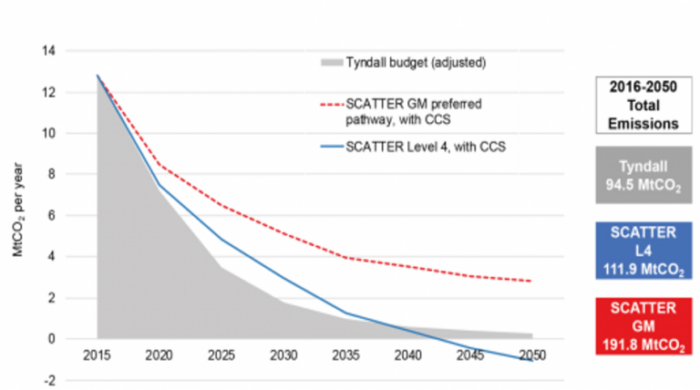

This research was motivated by various reports presented in the technical literature in the last decade, where a general increase of harmonic levels has been observed. A similar trend has been reported in several countries, simultaneously to the installation of increasing levels of renewable energy sources and other inverter-based devices. These reports have created some concerns about harmonic management in the future, when more renewable energy sources will be in services. Ultimately, the project aims at forecasting harmonic levels in 2050, and at determining impact on the equipment, and possible mitigating solutions.

Collaborating parties

This case study involved the collaboration between the Department of engineering at King’s College London and National Grid UK.

Project set up

Power quality is a specialist area within power systems that deals with deviation of voltage and current waveforms from the nominal values, in terms of both amplitude and frequency. The academic PI worked for a few years in the power industry, with the aim of specialising in power quality and understanding the issues faced by the power industry, as well as the tools that are used to carry out power system studies. The industrial PI is an expert in the area of power quality and has been involved with many standardisation groups as well as professional organisation to help developing common tools to harmonise the approach to power quality. Therefore, the two PIs have a similar expertise and background that allowed them to discuss and define common areas of research. When looking to develop such a specialist project, it is very important that all parties involved have a common ground, so that it is possible to interact and work in the same direction.

Outcomes

The project is still not finished, however, some of the original objectives have been achieved:

- A 2050 scenario has been developed, by using: transmission system model data provided by National Grid, device models developed through research and testing, and identification of future locations of renewable energy sources. Although the case is still under development, preliminary results indicate that harmonic levels are expected to increase, but they can be managed using existing design practice.

- A distribution system model with harmonic injection has been developed and it is currently under discussion with the industrial partner. This model is needed by the industrial partner to be able to represent the presence of renewable energy sources on the power grid at lower voltage levels.

- This was the first collaboration between the academic and the industrial PI, and was very positive and constructive for both parties. Therefore, the two collaborators now planning to continue this collaboration via other projects in the future.

Lessons learned, reflections, recommendations

- In terms of technical developments, the collaboration has been very productive, as it allowed the exchange of information between industry and academia. Specifically, the industrial partner provided data and models that are used by power system engineer working at National Grid to carry out renewable integration studies. This information cannot be found in the literature as it is protected by NDAs. On the other side, the university provided expertise in developing models that can be used to represent specialist equipment, and that are needed to study the integration of renewable energy sources. Development of such models is time consuming, and the support of the university allowed faster development and testing.

- COVID impacted the collaboration because, as part of the original project plan, placements in industry were to be carried out. However, ultimately they didn’t take place. The industrial placements would have helped the model development to proceed faster as it would have allowed closer communication. The use of remote meetings mitigated the impact of COVID and still allowed the project to be carried out successfully. For any project of this type, it is very important to be able to work closely with the industrial partner and being able to meet regularly. Being in the same office allows to discuss more frequently, rather than waiting for formal meetings to be set.

- For a technical project aiming at analysis a very-well defined problem, one recommendation is to find the technical experts within the company that can provide expertise. This may take some time in the initial stages, but at the end it will pay off as it will allow to carry out meaningful technical discussions.

Further resources

We published two papers and others are in preparation:

- Z. Deng, G. Todeschini and K.L. Koo: ‘Modelling Renewable Energy Sources for Harmonic Assessments in DIgSILENT PowerFactory: Comparison of Different Approaches’, 11th International Conference on Simulation and Modeling Methodologies, Technologies and Applications.

- Z. Deng, G. Todeschini and K.L. Koo: ‘Comparison between Ideal and Frequency-dependent Norton Equivalent Model of Inverter-Based Resources for Harmonic Studies’, 2021 IEEE Innovative Smart Grid Technologies Conference Asia.

Any views, thoughts, and opinions expressed herein are solely that of the author(s) and do not necessarily reflect the views, opinions, policies, or position of the Engineering Professors’ Council or the Toolkit sponsors and supporters.