Theme: Knowledge exchange, Universities’ and businesses’ shared role in regional development, Collaborating with industry for teaching and learning

Theme: Knowledge exchange, Universities’ and businesses’ shared role in regional development, Collaborating with industry for teaching and learning

Authors: Ben Ricketts (NMITE), Prof Beverley Gibbs (NMITE) and Harriet Dearden (NMITE)

Keywords: Challenge-based Learning, Timber Technology, Levelling-up, Skills, Future of Work

Abstract: NMITE is a greenfield engineering-specialist HEI in Herefordshire which welcomed its first students in September 2021. Partnership is key to our growth, from both necessity and choice. Our MEng Integrated Engineering is infused with partners who facilitate a challenge-based learning pedagogy, and our Centre for Advanced Timber Technology (opening September 2022) works in national partnership to deliver a curriculum developed by – and for – the timber engineering industry. Alongside a rich educational offer, NMITE’s greenfield status brings with it the responsibility to contribute to civic and economic growth. We are a named partner in Western Power Distribution’s Social Contract as we pursue shared goals for regional development and reduced economic inequality. Key to our goals is our role in in Hereford’s Town Plan, leading an initiative called The Skills Foundry which will promote community engagement around individual skills, and with businesses in the changing nature of work.

NMITE is a greenfield HEI founded to make a difference to the people of Herefordshire and to its economy. Herefordshire is characterised by lower-than-average wages, lower-than-average skills, higher proportions of part-time work, a GVA gap of £1.75bn[1], and is categorised as a social mobility coldspot [2]. Into this context, NMITE was launched in 2021 without any antecedent or parent organisation, and with an engineering and technology focus whose graduates would help address the national shortfall of engineers. We see ourselves as educators, educational innovators, a catalyst for upskilling, and agents for regional change.

An HEI founded in partnership

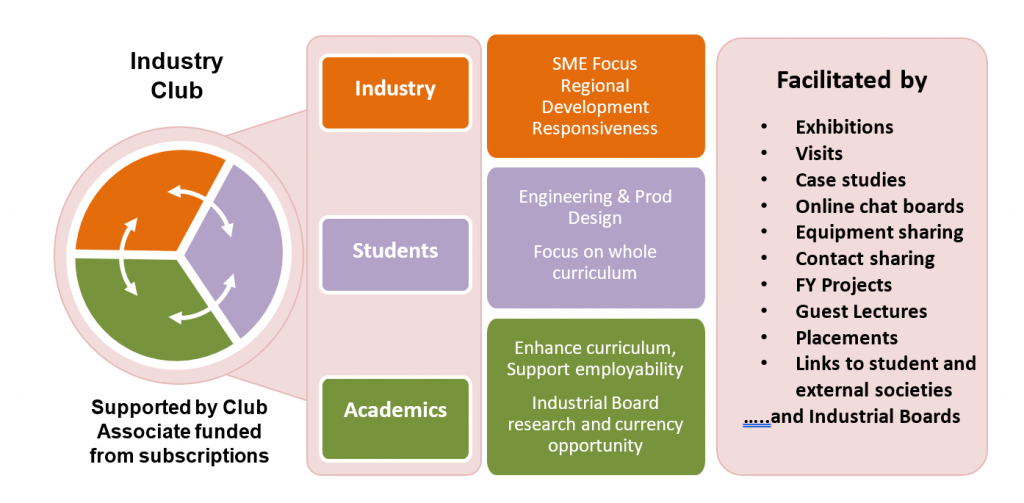

From NMITE’s earliest days, building strong relationships with partners has been a core part of our culture. NMITE’s first supporters were industry partners, a mixture of local SMEs and national and international companies with a regional presence, united by the need for access to a talent pipeline of engineering graduates. The urgency of this need was evidenced in the raising of over £1M of seed funding, from a range of businesses and individuals. This early investment demonstrated to Government and other stakeholders that the concept of an engineering higher education institution in Hereford had industrial support. In turn, this unlocked significant Government funding which has subsequently been matched through donations and sponsorship to NMITE.

Over the last five years, the portfolio of partners has continued to grow. The nature of the support spans equipment, expertise and financial donations. Our Pioneer Fund raised money to support NMITE’s first students, with donations recognised through naming opportunities. For NMITE, this enabled us to offer universal bursaries to our students joining in our first two years of operation – a powerful tool in student recruitment, and with a longer-term outcome for those early investors in their ability to develop relationships with students, increase their brand awareness and achieve their own recruitment targets in the future.

Curriculum Partnerships

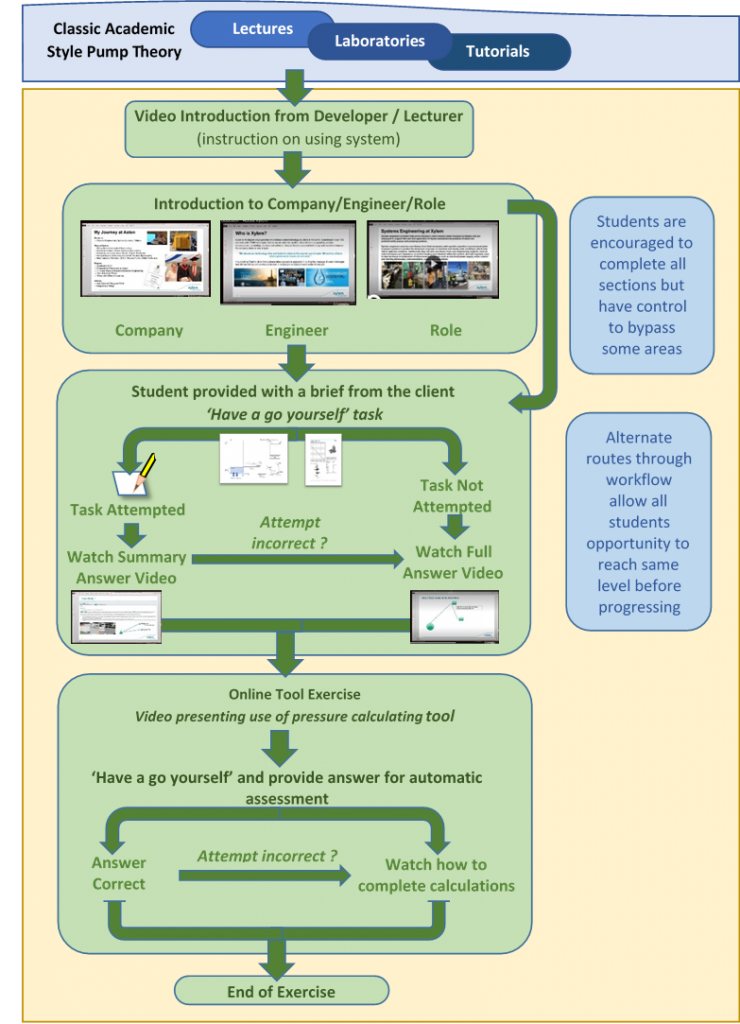

NMITE welcomed its first MEng students in September 2021, and this has provided new opportunities for industrial partnership in the curriculum. The MEng Integrated Engineering is a challenge-led pedagogy where learners work in teams to address real engineering challenges provided by an industrial (and occasionally community) partner. During the process, learners have direct contact with professionals to understand commercial pressures and engineering value, apply theoretical knowledge and develop professional capabilities.

In the sprint-based MEng, NMITE learners tackle around 20 different challenges in this way. Since September, our first students have helped re-engineer the material on a torque arm, designed and built a moisture sensor for a timber-framed house, visualised data from a geotechnical survey, and validated/optimised their own designs for a free-standing climbing structure. Students are already building their portfolio of work, and employers are building relationships with our student body.

Amplifying Innovation

Whilst NMITE is comfortable in its positioning as a teaching-focused HEI, we are mindful of the contribution we can make to the regional economy. NMITE has benefitted from LEP investment to support regional skills and productivity [3], and we have identified opportunities in advanced timber technology, automated manufacturing and skills for a changing future of work.

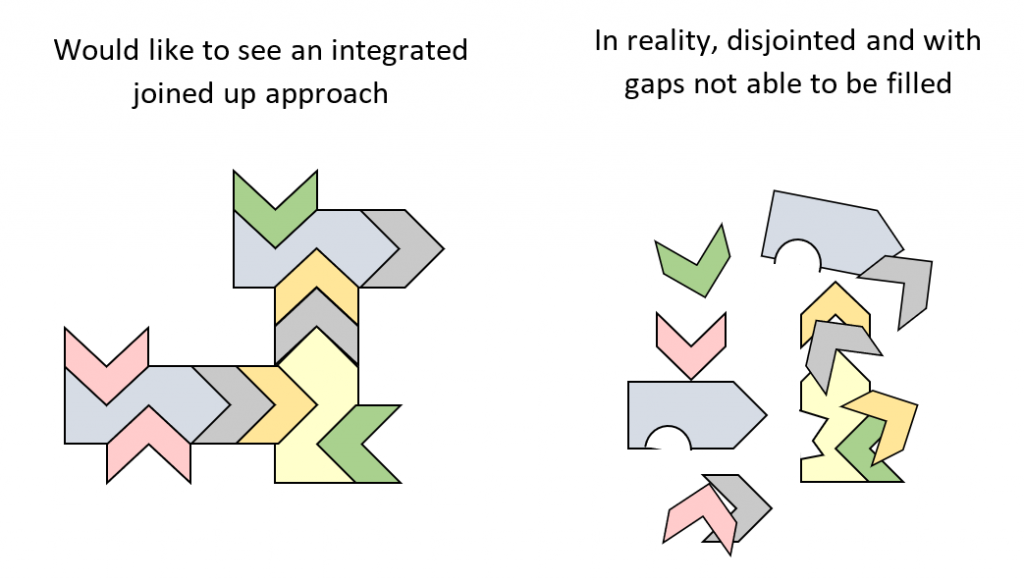

The Centre for Advanced Timber Technology (CATT) will open in September 2022 on Skylon Park, Hereford’s Enterprise Zone. Drawing on insight from a series of round table meetings with global and national businesses in timber, we came to understand that the UK timber industry needed to be much better connected, with more ambitious collaboration across the industry both vertically (seed to end product) and horizontally (between architects, engineers and construction managers, for example). In pursuing these aims we once again opted for a partnerships-based approach, forging close relationships with Edinburgh Napier University – internationally recognised for timber construction and wood science – and with TDUK – the timber industry’s central trade body. Founded in this way, CATT is firmly rooted in industrial need, actively engaged with industrial partners across the supply chain, and helps join up activity between Scotland, England and Wales.

CATT’s opening in 2022 will spearhead NMITE’s offer for part-time, work-based learners (including professionals, reskillers and degree apprentices) and provide a progressive curriculum for a sustainable built environment. In keeping with NMITE’s pedagogical principals, the CATT’s curriculum will be infused with a diverse portfolio of industrial partners who will provide challenges and context for the CATT curriculum. In future years, the Centre for Automated Manufacturing will provide educational options for comparable learners in the manufacturing industry.

Our initial research in establishing need in these areas pointed not only to skills shortages, but to technological capacity. Herefordshire has a very high proportion of SME’s who report difficulties in horizon scanning new technologies, accessing demonstrations, attracting and retaining graduates with up-to-date knowledge. In this space, and an HEI can play a key role in amplifying innovation; activities to support this will be integral to NMITE’s work at Skylon Park.

The Changing Nature of Work

NMITE is active in two further projects that support the regional economy and social mobility, founded in the knowledge that today’s school leavers will face very different career paths and job roles to those we have enjoyed. Automation, globalisation and AI are hugely disruptive trends that will change opportunities and demand new skills.

NMITE’s ‘Herefordshire Skills for the Future’ project is funded by the European Social Fund and helps SMEs, micro-businesses and young people to develop and secure the skills needed to flourish in the economy of 2030. Activities include:

- skills audits for SMEs and creation of bespoke action plans

- early career leadership development courses and networking

- upskilling in entre- and intrapreneurship capabilities

- significant upscaling of high-quality work experience for school and college students and careers advice

NMITE’s Future Skills Hub is a central element of the Hereford Stronger Towns bid [4] to the Government’s Towns Fund, a flagship levelling-up vehicle. The overarching goal of the hub is to provide access to skills and improve employment opportunities for Herefordians, in the context of changing job roles and opportunities.

Conclusion

Our core mission of innovation in engineering education is enhanced by our civic commitment to regional growth and individual opportunity. From the outset, NMITE has been clear that to meet business demand for work-ready engineers, business must contribute meaningfully to their development. We aim to contribute to closing the gap in regional, national and global demand for engineers, but without that critical early investment from partners we would not have been in the position to establish the radical institution that NMITE is today, that remains so close to the original vision of the Founders.

[1] Herefordshire Council. Understanding Herefordshire: Productivity and Economic Growth, 2022. Available online at Productivity and economic growth – Understanding Herefordshire [accessed 17th January 2022]. [2] [1] Herefordshire Council. Understanding Herefordshire: Topics Related to Social Mobility, 2022. Available online at Topics relating to social mobility – Understanding Herefordshire [accessed 17th January 2022]. [3] Marches Local Economic Partnership. Marches LEP backs NMITE project with £5.66m funding deal. Available online at Marches LEP backs NMITE project with £5.66m funding deal – Marches LEP [accessed 17th January 2022]. [4] Stronger Hereford. #StrongerHereford – The independent Towns Fund Board for Hereford

Any views, thoughts, and opinions expressed herein are solely that of the author(s) and do not necessarily reflect the views, opinions, policies, or position of the Engineering Professors’ Council or the Toolkit sponsors and supporters.