Objectives: To equip learners with the skills to successfully navigate digital and traditional recruitment processes for engineering roles. This includes demonstrating EDI, technical, and employability skills using the STAR framework; tailoring CVs for AI and Applicant Tracking Systems (ATS); and preparing for aptitude and abstract reasoning tests through targeted practice to enhance problem-solving and analytical abilities.

Objectives: To equip learners with the skills to successfully navigate digital and traditional recruitment processes for engineering roles. This includes demonstrating EDI, technical, and employability skills using the STAR framework; tailoring CVs for AI and Applicant Tracking Systems (ATS); and preparing for aptitude and abstract reasoning tests through targeted practice to enhance problem-solving and analytical abilities.

Introduction: Large national and international employers use digital application processes to recruit graduates. These digital applications aim to capture personal details, education, and work experience. Reflect on your experiences to demonstrate your EDI, employability, and technical skills applied using the STAR (Situation, Technique, Action, and Result) framework. Smaller and medium enterprises typically seek cover letters and CVs.

Topic: Navigating digital recruitment in engineering: CVs, AI, and aptitude tests.

Keywords: Equity Diversity and Inclusion; Employability and skills; Problem solving; Assessment criteria or methods and tools; CVs and cover letters; Digitalisation; Artificial intelligence; Information and Digital literacy; Communication; Technical integration; Writing skills; Inclusive or Responsible design; Neurodiversity; Curriculum or Course; Computer science; Computing; Engineering professionals; Professional development; Recruitment; Digital engineering tools; Business or trade or industry; Workplace culture

Master the art of applying for engineering computing jobs

In the video below, Professor Anne Nortcliffe explains how to develop expertise in securing engineering computing positions by demonstrating technical proficiency and employability skills through well-supported, evidence-based responses.

Video summary:

Master the art of applying for engineering computing jobs by showcasing both technical and employability skills through evidence-based responses.

Key insights:

⚙️AI in hiring: Understanding that many companies use AI for initial screenings emphasizes the need for clear, evidence-based answers in applications.

✏️Individual contributions: Highlighting personal achievements rather than team efforts showcases leadership and initiative, key traits employers seek.

💡Interpersonal skills: Employers value teamwork and leadership; demonstrating how you’ve influenced others highlights your potential as a valuable team member.

⭐STAR methodology: Using the STAR method helps structure your experiences into compelling narratives, making it easier for employers to assess your qualifications.

🗒️Tailored applications: Customising your CV and cover letter for each job application reflects your genuine interest and ensures relevance to the employer’s needs.

📚Professional etiquette: Ending your application with gratitude and a clear call to action maintains professionalism and shows your enthusiasm for the role.

AI and Applications

To navigate digital recruitment, it’s crucial to understand AI’s role in candidate screening. Tailor your CV to pass AI and Applicant Tracking Systems (ATS) using resources that provide insights into keywords, formatting, and strategies. This enhances your visibility and competitiveness in the digital recruitment process.

Further links to look at:

- Who Uses ATSs & How to Spot Them: Uncover the workings of AI used in the recruitment process.

- Presenting Your CV for the Machines: Master the art of crafting a CV that appeals to both human recruiters and AI systems.

- Tricks Recruiters Use to Filter Applicants: How you can navigate the effective strategies used by recruiters.

- E-applications: What’s in a File?: Understand the technicalities of and how to optimise electronic applications

Please note that after clicking these links, you will need to create a free account on the external website to access the materials.

CV and Covering Letter

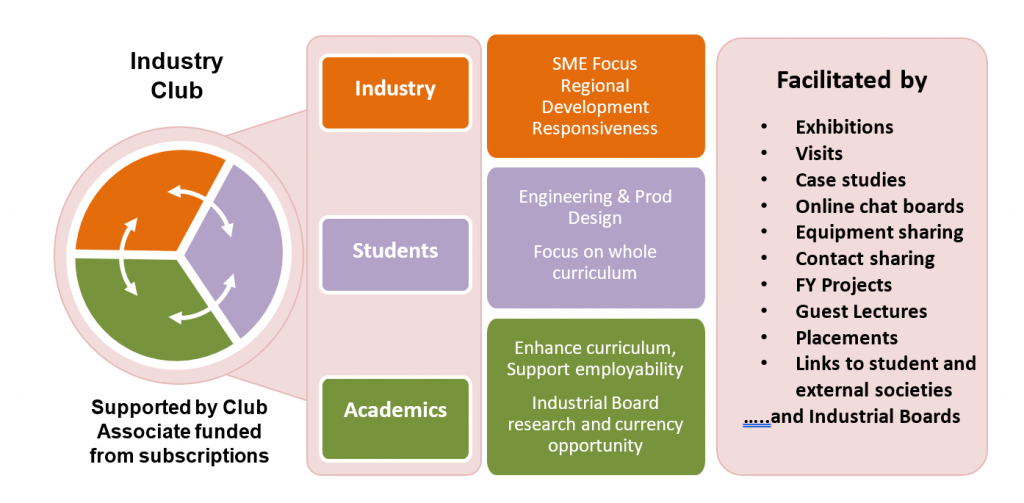

CV templates to support students and graduates to stand out and highlight their engineering and technology capabilities, especially when applying to Small and Medium Enterprises (SMEs) that do not use AI recruitment tools.

For applications to large corporations that use AI recruitment tools, it is recommended:

- Use a plain text CV.

- Include a web link to your LinkedIn profile or personal portfolio showcasing your engineering and technology capabilities.

- Digitally watermark all items in your portfolio to protect your intellectual property (IP).

Aptitude and Abstract Reasoning Test

If your digital application is successful you will be typically invited to complete an aptitude and abstract reasoning tests to evaluate candidates. To excel, practice brain training exercises and brain teasers to enhance problem-solving, critical thinking, and analytical skills. Regular practice with similar questions boosts confidence and performance, improving your chances of passing these tests and standing out in the recruitment process.

Further links to look at:

- Train your brain with brain gyming

- Discover what you brain can do

- Seventeen free aptitude tests

- Institute of Psychometric Coaching - free aptitude tests

- Sample of abstract reasoning tests (To access the complete test, you will need to purchase the full package)

- Free abstract reasoning tests

This work is licensed under a Creative Commons Attribution-ShareAlike 4.0 International License.

Any views, thoughts, and opinions expressed herein are solely that of the author(s) and do not necessarily reflect the views, opinions, policies, or position of the Engineering Professors’ Council or the Toolkit sponsors and supporters.

Please note: Discussions around discrimination, prejudice and bias are highly complex and part of a much wider national and international debate, including contested histories. As such, we have limited the scope of our resources to educating and supporting students.

The resources that the EPC and its partners are producing in this area will continue to expand and, if you feel there is an issue that is currently underrepresented in our content, we would be delighted to work with you to create more. Please get in touch.