Northumbria University

Keywords: Cold-Rolled Steel (CRS), Structural Optimisation, Finite Element Modelling, Experimental Testing, Sustainable Construction, High-Yield Strength Steel, Design Guidelines, Material Efficiency, Modular Building Systems and Academic-Industry Collaboration.

Sector: advanced manufacturing

Project leads: Dr Keerthan Poologanathan, Associate Professor; Dr Muhammad Rahman, Associate Professor; Dr Vikki Edmondson, Associate Professor; Dr Elilarasi Kanthasamy; Mr. Kajaharan Thirunavukkarasu; Mr. Kannan Thushanthan

Project collaborators: Doby Verrolec Ltd; University of Northumbria at Newcastle

Issues addressed by the project

Doby Verrolec aimed to develop sustainable Cold-Rolled Structural Steel (CRS) innovations to expand its product portfolio. The focus was on creating new section profiles that reduced material use while improving structural performance. This required cutting-edge theory, research-driven innovation, and specialist academic expertise beyond traditional consultancy.

Combining academic research with the company’s industry knowledge enabled a multidisciplinary approach: material testing, design analysis, advanced modelling, and full-scale testing. The results gave Doby Verrolec international recognition, with products adaptable to local regulations by addressing core requirements rather than relying solely on extensive testing.

Future impact of the project

The project developed high-yield strength Cold-Rolled Steel (CRS) channel sections that use less material, reduce embodied carbon, and lower manufacturing and transport costs, while improving structural performance and buildability. These sections replace conventional steel profiles in structural and non-structural applications, meeting requirements for floor joists and roof purlins more cost-effectively. Their enhanced properties support building regulation compliance and promote light steel framing as a preferred construction method.

A robust scientific foundation replaced the need for extensive experimental validation, addressing complex failure modes and testing challenges. The outcome was a novel, efficient, and sustainable channel section profile that ensures safety, cost-effectiveness, and environmental benefits. The project also set the stage for future optimisation and modelling, with the university-industry partnership continuing to drive innovation.

Place-based local and regional benefits

The project boosted local manufacturing by enabling a County Durham-based SME to develop innovative high-yield strength CRS sections, expanding its product range, competitiveness, and potential for increased production and jobs. It strengthened the local supply chain and contributed to regional economic growth. Collaboration with Northumbria University fostered academic-industry links, providing PhD researchers with hands-on experience in structural engineering, finite element modelling, and sustainable design skills valuable to the regional workforce.

Environmentally, the project reduced material use and embodied carbon, supporting sustainable construction and compliance with modern building standards. Access to the university’s advanced testing facilities and software reinforced the region’s R&D capacity, laying the foundation for ongoing innovation. Overall, it delivered economic, environmental, educational, and infrastructure benefits to the region.

National and global benefits

Nationally, the project advanced the UK’s goals in sustainable construction and advanced manufacturing by developing high-yield strength CRS sections that use less material and have reduced embodied carbon. These innovations support carbon reduction targets, align with policies on energy efficiency and material optimisation, and strengthen the UK’s industrial capability with an optimised steel product for infrastructure, housing, and modular construction. Comprehensive design guidelines equip engineers with tools to improve safety, efficiency, and cost-effectiveness in national projects.

Globally, the project positioned the sponsor as a leader in steel innovation, offering lighter, stronger, and more sustainable alternatives to conventional steel profiles. This work addresses worldwide construction challenges, influences global standards, and contributes to international knowledge in structural engineering and sustainable design. By reducing material use and carbon footprint, the project supports climate goals and the creation of greener cities. The academic-industry collaboration serves as a model for driving sustainable development through targeted research and innovation.

Level of investment and timescale

The project involved a total investment of about £38,000, including £4,500 from the business partner for supervisory and travel costs. Delivered over four months, it progressed through three stages: literature review and market analysis; full-scale testing and numerical modelling; and simulation, parametric study, and design guideline development.

Risks vs reward

Risks included uncertainties in the structural behaviour of the new CRS sections, the complexity of testing and finite element modelling, and potential resistance from the construction industry due to strict regulatory standards.

The rewards, however, were significant: an optimised high-yield CRS section with reduced material use, lower embodied carbon, and improved structural performance, offering cost savings and supporting sustainability goals. Design guidelines added long-term value by enabling wider industry adoption. Given the modest investment, short timescale, and high potential for commercial, environmental, and societal benefits, the project represented a well-balanced, strategically sound initiative.

Further aspects

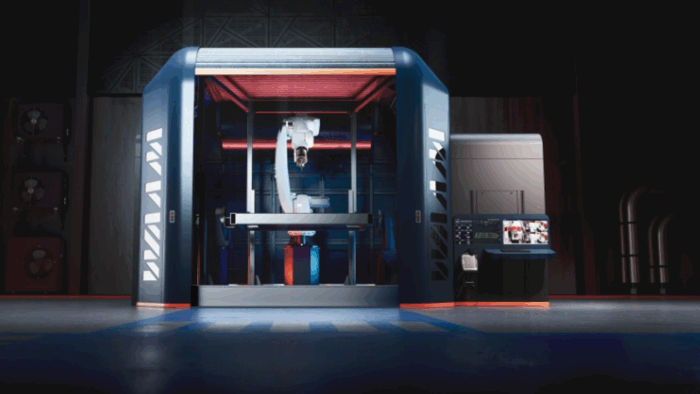

The R&D collaboration between Doby Verrolec Ltd and Northumbria University developed innovative high-yield strength CRS channel sections using full-scale testing, advanced computational modelling, and parametric studies. By integrating structural engineering, material science, and sustainability, the project optimised structural performance while reducing material use and embodied carbon.

A key output was the creation of comprehensive design guidelines, giving engineers practical tools to apply the new profiles efficiently and safely in real projects. These guidelines support sustainable construction, improve design accuracy, and encourage wider adoption of light steel framing.

The partnership strengthened academic-industry links, providing PhD researchers with hands-on experience in industrial R&D and enhancing skills in structural analysis, finite element modelling, and sustainable design. Access to the university’s advanced laboratories and software ensured high-quality, evidence-based results.

The work addressed technical challenges, including complex structural behaviour under bending, stringent safety in testing, and the conservative nature of industry adoption. Despite these risks, the project achieved strong commercial, environmental, and societal impacts, positioning Doby Verrolec as a leader in steel innovation and contributing to both UK and global sustainability goals.